That’s a great question; let’s unpack it.

If you’ve been around the protective coatings industry and follow our ChemLINE® and MarineLINE® Coating Brands, then we’re certain you’ve heard the term ‘crosslinking’ a great deal.

Crosslinking in a coating refers to the chemical process of creating bonds between the molecules within the coating material, typically covalent bonds. These bonds form a three-dimensional network structure called a polymer matrix or crosslinked network.

Crosslinking is important in coatings for several reasons:

- Mechanical Strength: Crosslinking in coatings enhances mechanical strength by creating a three-dimensional network of interconnected polymer chains. The crosslinked structure increases the overall strength and rigidity of the coating, making it more resistant to deformation. This is particularly crucial in industrial and marine applications where coatings are subjected to mechanical stresses, such as impacts, vibrations, and compression forces.

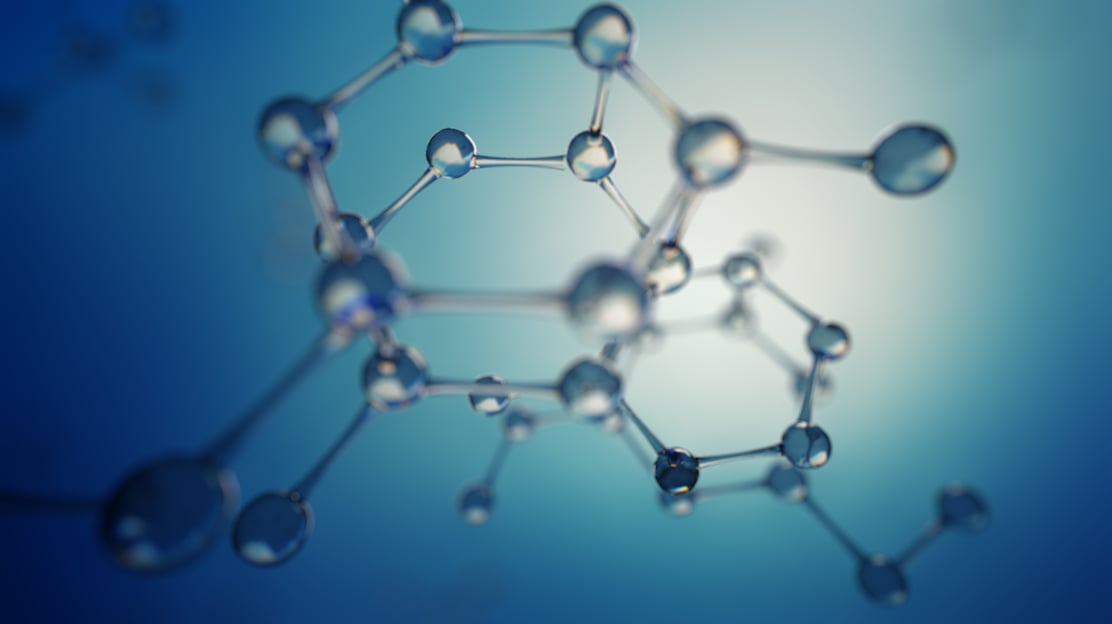

- Chemical Resistance: Crosslinking improves the chemical resistance of coatings by reducing their susceptibility to chemical attack or degradation. The crosslinked structure forms a barrier that prevents the penetration of corrosive substances, solvents, acids, alkalis, and other chemicals. This is vital in industrial and marine environments where coatings come into contact with various aggressive substances, such as oils, fuels, saltwater, acids, and industrial chemicals.

- Abrasion Resistance: Higher crosslink density significantly improves abrasion resistance. This hard surface also significantly enhances the ability of the coating to be cleaned in less time. The crosslinked structure creates a dense and tough surface that can withstand friction, wear, and abrasion caused by mechanical contact, sand, particles, or rough surfaces. This is essential in industrial and marine settings where coatings are exposed to abrasive conditions, such as constant rubbing, sliding, or impact with solid objects.

- Increased Hardness/Toughness: Crosslinking can significantly increase the hardness of coatings. The formation of crosslinks strengthens the polymer matrix, making the coating more rigid and resistant to deformation. The increased hardness protects against scratches and surface damage. Increased hardness contributes to their longevity and performance in industrial and marine applications, where coatings are exposed to demanding conditions.

Overall, crosslinking plays a crucial role in industrial and marine coatings by enhancing mechanical strength, chemical resistance, abrasion resistance, impact resistance, resistance to cracking, and increasing hardness and toughness. These properties are essential for ensuring coatings' durability, protection, and performance in challenging and harsh environments.

Utilizing our patented Gridlock Technology™, our ChemLINE® and MarineLINE® Coatings provide 4-7 times more reactive sites per polymer versus the competition to generate the level of crosslinks that drive superior performance characteristics.

To read more about our patented Gridlock Technology™, click here.

Have something you've been curious about regarding our ChemLINE® and MarineLINE® Coating Systems? If so, click the button below to ask us your questions - and don't worry - this is completely anonymous.