About

Our mission is to provide you with innovative, value-added coatings to protect your assets while also increasing your Return on Investment (ROI).

Serving the Chemical Tanker, Product Tanker & Barge Markets

Industry coatings engineered to protect your assets.

Serving the Transportation, Petrochemical, Secondary Containment & Other Markets

Applications

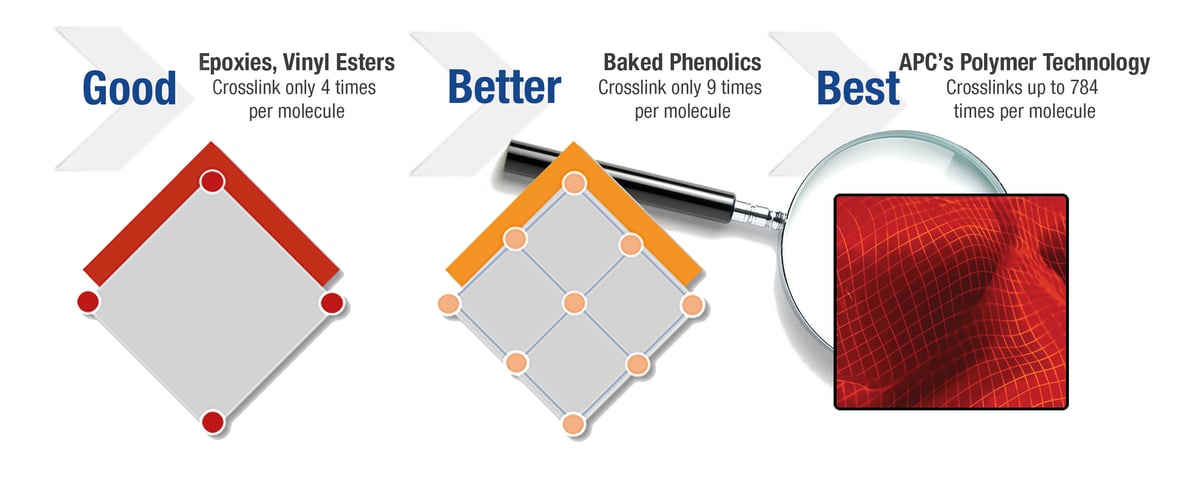

Patented technology and the highest cross link density means our coatings are engineered to protect your assets no matter what market you are in.

- Marine

Chemical tankers and product tankers, as well as barges - Industrial Coatings

An Industrial Coating That Help You Increase Operational Uptime - Tank Linings

A Tank Lining System To Store Your Aggressive Cargoes & Maximize Your ROI - ISO Tank Linings

A Proven ISO Tank Lining System To Successful Carry Your Aggressive Cargoes - Truck Linings

A Proven Truck Tank Lining System To Successful Carry Your Aggressive Cargoes - Rail Tank Linings

A Rail Tank Lining To Transport Chemicals & Maximize Your Efficiency - Industrial Flooring & Secondary Containment

An Industrial Coating That Help Protect Your Floors and Secondary Containment Areas Against Chemicals -

- BPA Free Food Grade Tank Lining

A Tank Lining System To Protect You Food Grade Storage Tanks

Resources

Our resources provide answers to questions you may have. Contact us with any further inquiries.

- Chemical Resistance Guide

Find out if our protective coatings are right for your project. Search by either MarineLINE® or ChemLINE® - Case Studies

Explore all our Coatings Case Studies and see how our customers protect their assets. - Product Data Sheets

Search both MarineLINE® and ChemLINE® Data Sheets and Resistance Guides. - Learning Hub

Get your questions answered. It’s designed to help you with your coating needs. - Blog

Learn something new or discover news or trends in the coating industry. - Customer Care

Unlock your MarineLINE® suite of services.