What is Secondary Containment?

Secondary containment includes any system, device, or control measure used to stop a discharge from leaving a specified area. It is an essential line of defense in the event of the failure of the primary containment, such as a bulk storage container, piping, a mobile or portable container, or oil-filled equipment.

Just as vital is protecting the areas in and around and underneath tanks, including concrete tank pads, flooring, secondary containment,

In this article, we review secondary containment best practices and scenarios where the use of polymer coatings for concrete and secondary containment will serve as a

Secondary Containment Regulations: Five Points to Consider to Maintain Compliance

Having a solid understanding of secondary containment regulations is crucial because it will help you be more prepared to help your facility achieve and maintain compliance.

Here are the five things you should consider regarding "The Secondary Containment Regulations," also known as the EPA 40 CFR 264.175.

-

The secondary containment system must be free of cracks or gaps and impervious.

-

Primary containers cannot sit in their waste. Secondary containment unit should be sloped or explicitly designed to quickly and easily remove leaking or spilled liquids.

-

Secondary containment system needs to contain at least 10% of the total volume of the primary containers or 100% of the volume of the largest container.

-

Must be able to prevent precipitation, also known as run-on, from entering the secondary containment system unless the system has sufficient capacity to contain "run-on" in addition to the volume capacity requirements.

-

Any spilled or leaked waste in the secondary containment area must be removed in promptly to prevent overflow.

The EPA provides further containment and secondary containment systems in the Resource Conservation and Recovery Act (RCRA), which can be found in Title 40 Code of Federal Regulations (CFR) Part 264.

Use Case Scenarios of Polymer Coatings for Concrete and Secondary Containment

Turkey's UDME Seeks to Safeguard Concrete Surfaces with ChemLINE®

At the GÜBRETAS fertilizer factory in Turkey, the manufacturing operations produce a range of fertilizers and related products used in the Turkish agricultural sector.

UDME consulted with APC to review what high-performance coatings would provide acid resistance on new concrete pads that will hold chemical tanks used in fertilizer production and the facility's surrounding areas.

APC also studied the cargo (chemicals) and temperature service conditions to monitor what types of

These conditions included:

- 18% Phosphoric acid

- 10% Hydrogen

sulfate-sulfuric acid - 98% Chlorine – fluoride

- Operating temperatures between 95˚C to 105˚C (203˚F to 221˚F)

All the concrete surfaces coated were new, covering more than 1,000 square meters of surface area. For heat curing ChemLINE® coatings in these large outdoor areas, APC built a protective enclosed area using plastic sheeting wrapped around the staging as

ChemLINE® Secondary Containment Protection in Turkmenistan

In Turkmenistan, one of the largest thermal power plant builders in the region specified ChemLINE® coating for concrete secondary containment protection. ChemLINE® was applied at three different power facilities in the cities of Ahal, Lebap,

At this new concrete secondary containment pit, the surface is first cleaned and prepared for the coating application.

Various chemicals are used at these facilities, including the following, and these are all safely contained with ChemLINE® :

- 98% H2SO4 (Sulfuric acid)

- 0-100% NaOH (Sodium hydroxide)

- 0-19% NaOCl (Sodium hypochlorite)

- 0-50% FeCl3 (Ferric chloride) at ambient temperature.

For these projects, APC first applied a ChemLINE® primer coat (blue color), with ChemLINE® (red color) next as the base coat, finished with ChemLINE® (grey color) as the top coat.

After the primer coat of ChemLINE® is checked, stripe coating of ChemLINE® (red color) is applied.

The containment areas are lined with a ChemLINE® base coat (red), followed by a ChemLINE® top coat (grey) to finish the protective lining application.

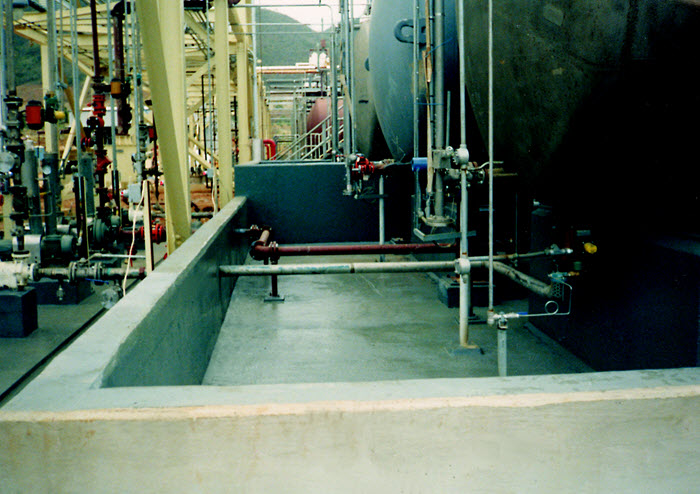

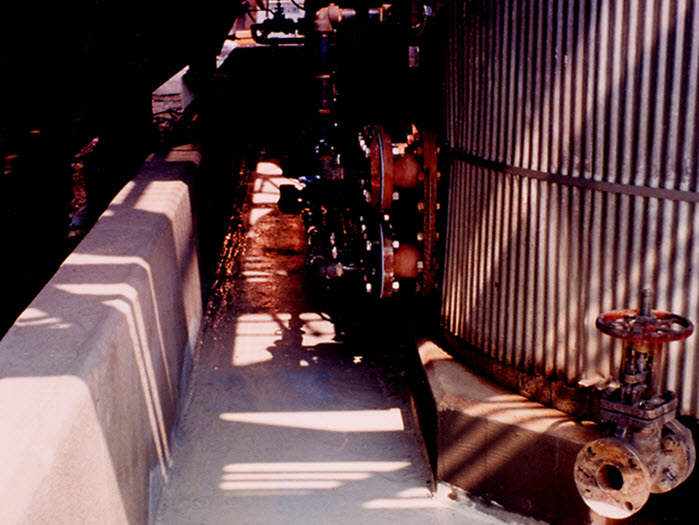

Additional Concrete Protection Projects

The following photos illustrate how ChemLINE® is also effectively used to protect a wide range of concrete and secondary containment areas. This protection is imperative for any bulk liquid storage facility, tank farm, or chemical processor that wants to meet regulatory compliance and protect the environment from the hazardous spills of chemical products.

ChemLINE® can be used for a range of different service applications.

The versatility of ChemLINE® can protect concrete surfaces in, around, and under tanks.

Conclusion

A secondary containment system's primary goal is to isolate hazardous chemical spills, splashes or leakage until they can be effectively handled. Because of the dangerous conditions, the secondary containment floor coating is essential.

At APC, we understand the need to protect concrete with a chemical-resistant coating. As a quality, premier coatings solutions provider, we provide innovative, value-added coatings to protect your assets.