Methanol accounts for approximately 25% of the seaborne petrochemical trade. It is expected to grow 6% per year by 2023. Because there are significant distances between major methanol manufacturing centers and key users, the oceans transport 80% of methanol.

However, air-absorbed moisture in the presence of inorganic salts causes methanol to be very corrosive to carbon steel cargo tanks.

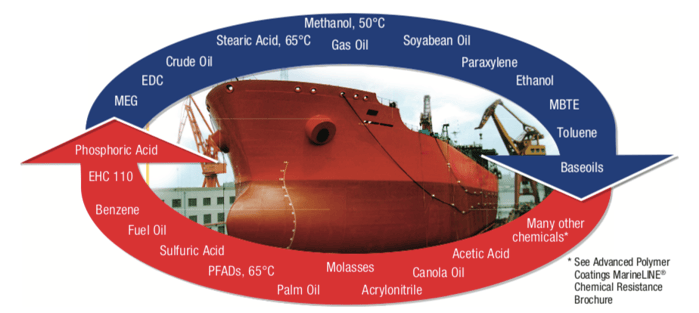

APC understands this challenge for shipowners and operators. With our MarineLINE® coating system, a versatile lining solution can be applied to carry profitable cargoes such as aggressive chemicals, methanol, and many others.

This article discusses safe methanol handling, including the history of the International Maritime Organization (IMO) and its Sub-Committee—Carriage of Cargoes and Containers (CCC), and the sequencing of cargoes to enhance your ROI.

Brief History of IMO and Methanol Safe Handling

The organization's purpose is to provide regulations and best practices concerning maritime safety, the efficiency of navigation, and the prevention and control of marine pollution from ships.

The IMO slogan sums up its objectives: safe, secure, and efficient shipping on clean oceans. It works through several sub-committees, including safe transportation of dangerous cargo, fire protection, and new ship design.

Until the mid-1980s, methanol was considered an 'unclassified chemical' by the IMO—no restrictions on the vessel type in which the chemical could be transported. Regulations were revised because of explosion concerns for products with flashpoints of 60 degrees Celsius or less. Methanol has a flashpoint of 16 degrees.

"The Sub-Committee keeps updated the International Maritime Solid Bulk Cargoes Code (IMSBC Code) and the International Maritime Dangerous Goods (IMDG) Code. It also keeps under review other codes, including the International Code of Safety for Ships using Gases or other Low flashpoint Fuels (IGF Code) and the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code). The Sub-Committee closely collaborates with other UN bodies dealing with the multimodal transport of goods." [source: Sub-Committee on Carriage of Cargoes and Containers (CCC)]

Regulations required vessels to use inert gas, which does not form chemical reactions with other chemical substances, during loading and unloading to prevent explosive air mixture in the cargo tanks. Today, the recommended best practice is that all newly constructed methanol tankers should be built with N2 inerting capability.

IMO assigns a grade to each cargo depending on its flammability, toxicity, corrosiveness, and reactivity. The carriage of a specific chemical requires the shipowner to check if that cargo matches the tanker's capabilities.

Shipowners must assess the various types of cargoes and plan to upgrade existing ships or purchase newbuilds to carry higher specification loads that mean more profit and provide more versatility.

Methanol safety precautions to be observed:

- Methanol must be stored in a dedicated location, protected from heat and ignition sources.

- It must be stored in a sealed container.

- Methanol must be stored in a bermed, diked, or bunded, well-ventilated area.

- Care must be taken in handling methanol, adding hydroxide, mixing hydroxide, and

then introducing the methoxide into the waste oil. - Temperature control throughout the process is critical to safe and efficient operation.

Resources:

Methanol Institute, Methanol Safe Handling Manual

Methanol Institute, Methanol Safe Handling Technical Bulletin

Capability to Backhaul After Carrying Methanol

Safety is the biggest consideration when carrying methanol in bulk. All methanol cargo should be maintained in an inert condition.

For shipowners to have a profitable experience carrying methanol, they also need to backhaul other cargoes on return voyages. MarineLINE® is in an excellent position to carry methanol without restrictions, and that is why it is the preferred lining choice today.

It can easily handle methanol on one voyage, and after a quick cleaning, then backhaul a wide range of different types of chemicals. This profitable sequencing of cargoes greatly enhances the ROI and profitability of the ship’s operation by gaining maximum value from the tanker asset. When needed, MarineLINE® coating can also carry methanol back-to-back on continuous voyages, another operating plus.

The chart below represents a few of the many sequencing possibilities with MarineLINE® . . .

MarineLINE® is formulated with a patented polymer formulation with high multi-functional capability. Once the coating is heat cured after application, it forms a highly cross-linked and tightly knit structure. This creates a nearly impermeable barrier lining (closed-screen structure) with high chemical and high-temperature resistance, even against the small molecule size of methanol.

Venting cargo tanks after carrying methanol can be a time-consuming problem for shipowners with conventional linings. With many types of linings, an extensive ‘rest period’ is required to ensure the tank lining is thoroughly desorbed and ready for the next cargo.

What to look for in your lining if you are transporting methanol . . .

- Tightly knit structure - Air-absorbed moisture in the presence of inorganic salts causes methanol to be very corrosive to carbon steel cargo tanks, which is why tanks need to be adequately protected. MarineLINE®’s unique, patented polymer technology creates a cross-linked and tightly knit structure to resist this type of attack.

-

Ease of cleaning - After carrying methanol in a MarineLINE® tank, a forced-air dry for 24 hours is usually all that is needed, so the tank can then be loaded with many other types of chemical and vegetable oil cargoes for its subsequent voyages.

One shipowner using MarineLINE® supports these statements and says . . .

“The versatility of MarineLINE® allows us to load any product on these vessels, in any sequence, without imposed constraints from the cargo tank configuration/coating. This is vital for our fleet efficiency.”

Related bonus content . . .

A key decision for owners of maritime chemical and product tankers is choosing the cargo tank lining/coating or tank material that delivers the highest return on investment (ROI). Read more on how marine coatings contribute to an owner's bottom line.

Get the PDF version to save to your desktop and read it when it's convenient for you. (No email required):

Cleaning Recommendations for Methanol

Before carrying methanol in MarineLINE® tanks, if tanks have been steamed, tanks must be allowed to cool to 30-40°C before loading.

After carrying methanol in MarineLINE® tanks, DO NOT STEAM. Force air dry for 24 hours.

Compare this performance versus other standard cargo tank coatings with more extended recovery periods to remove all ‘absorbed’ methanol.

MarineLINE® has an ultra-smooth, glossy, low-energy surface that reduces venting time and cleaning

after methanol carriage.

For more than 20 years, cargo tanks coated with MarineLINE® have been carrying methanol, and tanker shipowners and operators have testified to its success. After numerous onboard inspections, MarineLINE® has shown its long-life performance when properly maintained.

Different shipowners and operators tell more of their unique stories below.

The message is evident on the shipowner's need for a smooth, hard coating . . .

Another shipowner emphasizes the ability to carry methanol without restrictions . . ."We carry methanol especially, so we want to clean the tanks after discharge easily. MarineLINE® has a smooth, hard coating surface that handles methanol and can switch to other cargoes."

And an operator finds versatility number 1 on their list . . ."We are very upbeat about the MarineLINE® coating system as we carry methanol on one leg and caustic soda on the return leg. The voyage lasts about 6-7 days, and the vessels have been trading for about 4 years without problems. The main advantage of MarineLINE® is its ability to carry methanol and other cargoes without restrictions, which epoxies and zinc coatings cannot do."

And last, but not least—undoubtedly critical to the environment, this shipowner finds the eco-friendly lining a perfect match . . ." In our market, with so many short voyages being performed in a small defined area, this is key for success. The versatility of MarineLINE® allows us to load product on these vessels, in any sequence, without imposed constraints from the cargo tank configuration/coating. This is vital for our fleet efficiency."

MarineLINE® has proven to be the best tank surface coating for cleaning and easily switching cargoes, and fits perfectly with the eco-friendly nature of our tankers."

Online Chemical Resistance Guide Offers Fast Answers

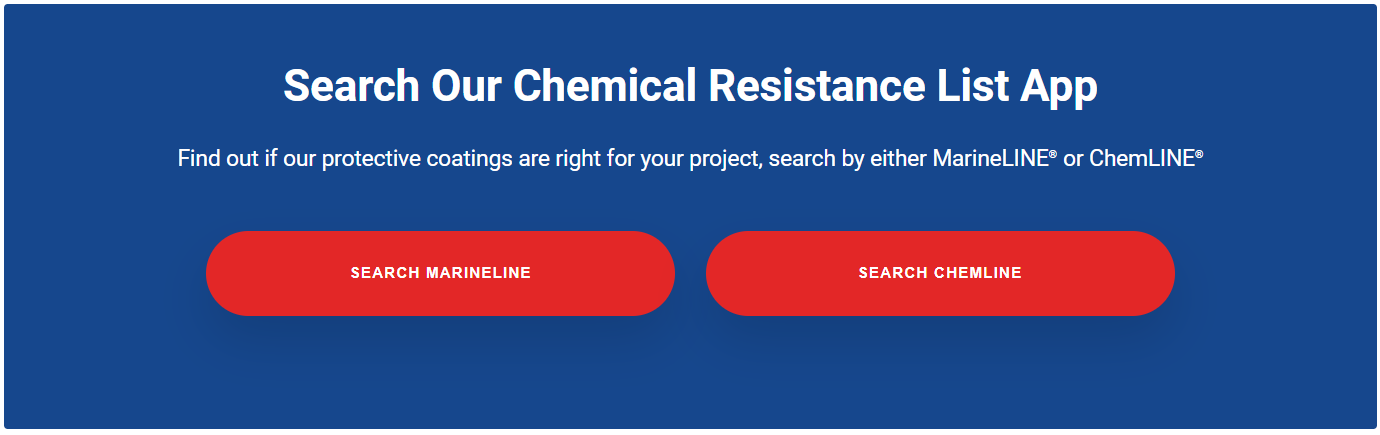

For more than 25 years, APC has provided chemical resistance guides (CRGs) in printed or PDF versions for its customers, covering both MarineLINE® and ChemLINE® coatings brands. Now, more than 2,800 of the most used chemicals are featured in our updated, searchable chemical resistance guide.

To access the CRG:

Step 1. Access the resource section here: Chemical Resistance Guides, MSDS & Application Specifications

Step 2. Search our chemical resistance list app. For example, click on "Search MarineLINE."

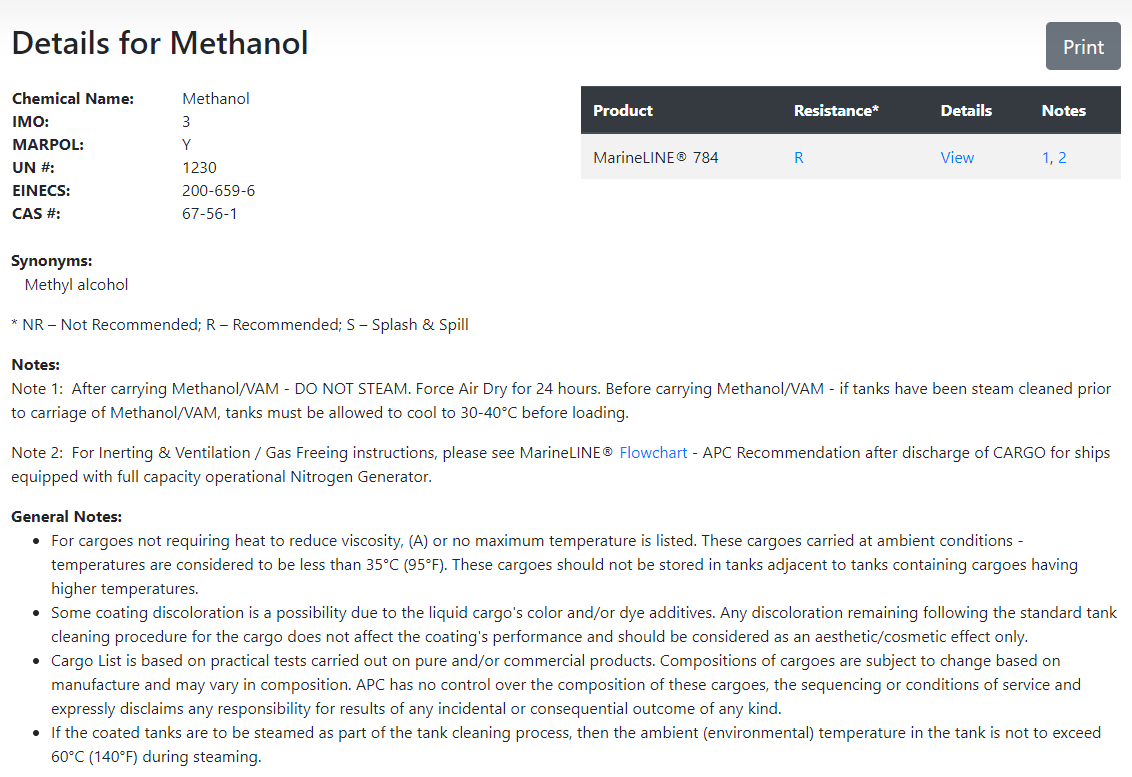

Step 3. Review the various categories that can include the following, as seen in this example search of the online database for ‘Methanol’: Chemical Name, IMO, MARPOL, UN #, EINECS, CAS #, Synonyms, Recommendations for Usage, and Notes.

For any chemicals not shown on the online CRGs, you will be able to contact APC for further information, or request a laboratory review.

Conclusion

The ability to move quickly between different cargoes and maintain a safe environment is always top-of-mind in the shipping industry. In addition, selecting the suitable coating extends the range of cargoes and reduces the time needed to switch between them.

Talk with your MarineLINE® representative to learn more about Methanol and other chemical carriages in your tankers.