Not only must the polymeric lining protect the vessel itself, but it must also preserve the purity of the carried cargo by limiting or eliminating contamination from a prior load. For polymeric linings/coatings, a very high crosslink density accomplishes this task.

In this article, we discuss crosslink density, absorption, and desorption of chemicals, and a case study on the potential contamination of vegetable oils.

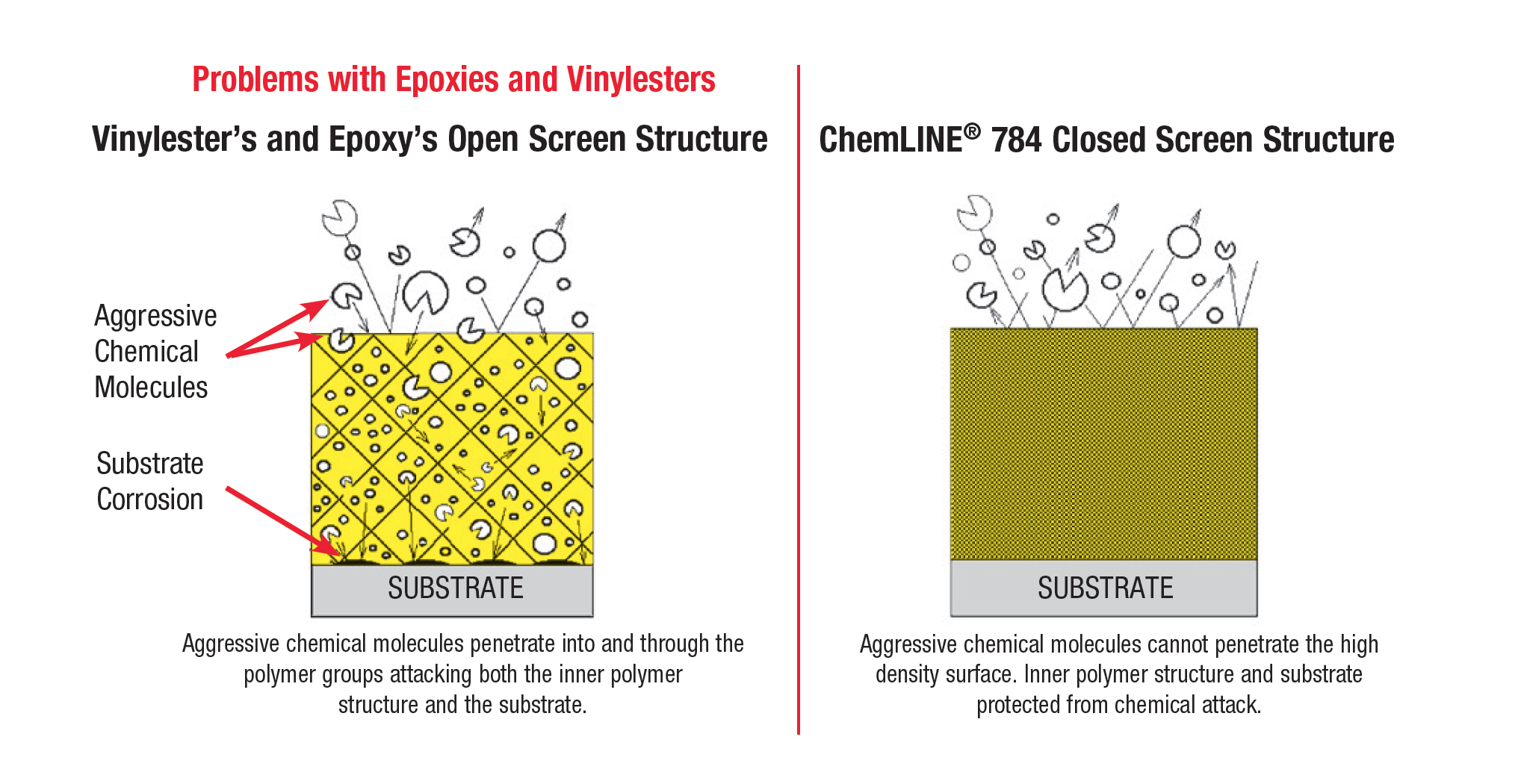

Penetration of Linings with Different Crosslink Density (Figure 1)

The lining on the left of Figure 1 represents a traditional lining from vinyl ester or epoxy, with a typical crosslink density. This crosslink density allows for penetration of chemicals into the lining, which can cause not only degradation of the lining itself through an attack on chemical bonds, but also damage to the substrate if the chemicals penetrate through the width of the lining and reach the substrate.

Today’s vessels must have the versatility to carry many different types of chemicals, but the prior cargo must not contaminate the chemical that is loaded into the vessel. Part of the potential for contamination, as seen in Figure 1, comes from absorption and desorption of chemicals. With a low to moderate crosslink density, chemicals are easily absorbed into the lining. Although the vessel is cleaned between loadings, there still may be chemicals absorbed into the lining that can be released or desorbed into the next cargo.

The cleaning method can influence the amount of chemical absorbed into the lining as well, with more aggressive cleaning methods releasing more of the absorbed chemical, but also presenting potential to damage the lining. In Figure 1, the lining on the right represents a polymer-modified lining such as MarineLINE® and ChemLINE® 784. With MarineLINE® and ChemLINE®’s polymer modification, up to 784 crosslinks are possible, compared to only four possible in a traditional bifunctional epoxy cured with an amine curative.

This high crosslink density forms a virtually impermeable barrier and prevents chemicals from absorbing into the lining. When the cargo is emptied, and the vessel is cleaned, there is no residual chemical absorbed into the lining to be desorbed upon loading of the next cargo.

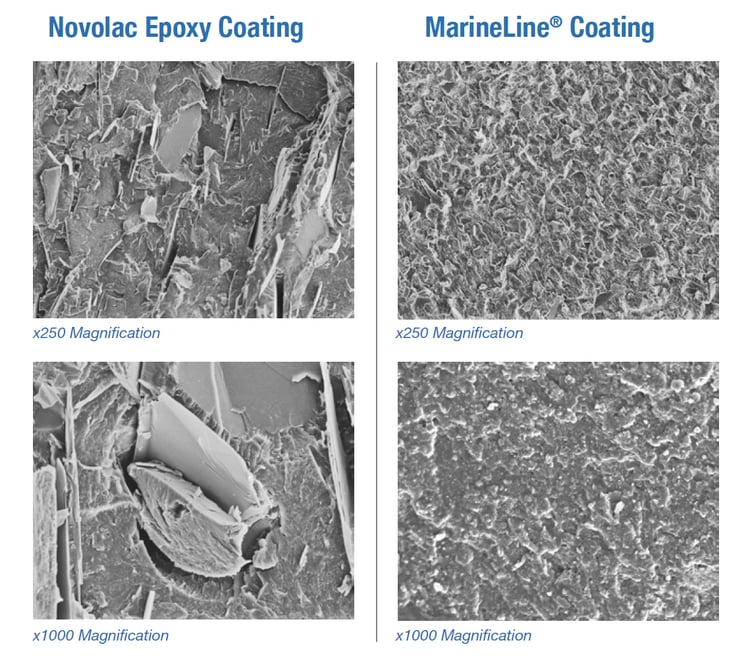

Scanning Electron Microscopy (SEM) of ChemLINE® 784/32

Figure 2 shows an SEM of a traditional epoxy

The traditional epoxy

SEM of Linings with Different Crosslink Densities (Figure 2)

Case Study: Protecting Vegetable Oils From Potential Contamination

As covered in our last blog post, vegetable oils are extremely important cargo in marine vessels, accounting for nearly 25% of the carriage market.

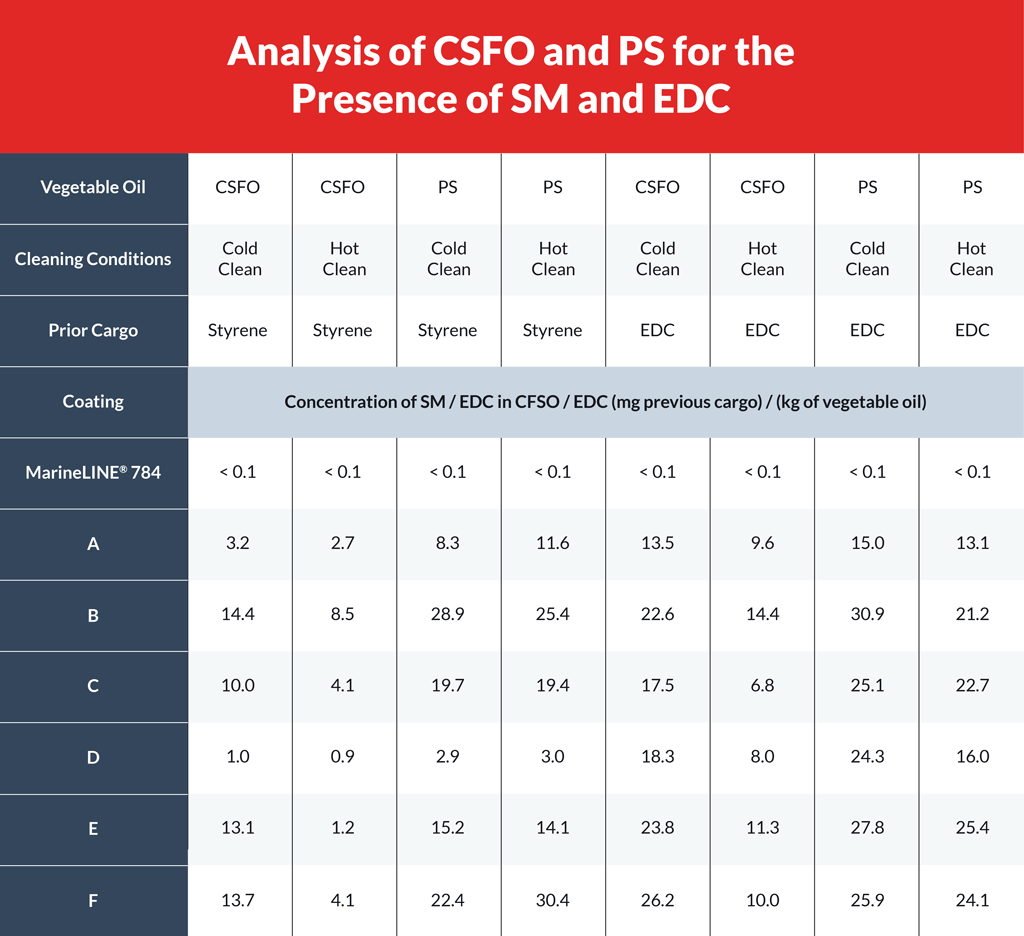

To quantify the potential contamination of vegetable oils from the desorption of previous cargo residues retained in organic cargo tank coatings, APC requested a study to be carried out by a UK based consultancy MarinSpec Associates Ltd.

In summary, test panels coated with a range of different organic cargo tank coatings, including MarineLINE® 784, were separately immersed into styrene monomer (SM) and ethylene dichloride (EDC) for 28 days at ambient temperature. These cargoes were specifically chosen because they are known to be strongly absorbed and retained in most organic paint films; indeed, there are restrictions on the carriage of food-grade vegetable oil after a vessel has carried either SM or EDC, which reflects these absorption/desorption characteristics.

After immersion the test panels were cleaned in two different ways, first using a “cold” washing procedure:

- 1-hour ambient seawater wash

- Ambient freshwater wash

- Natural ventilation for approximately 24 hours

And secondly using a “hot” washing procedure:

- 1-hour hot seawater wash

- 4 hours hot (60°C) seawater wash

- 2 hours steaming (maximum temperature of 55°C)

- Natural ventilation for approximately 24 hours

The reason for using these two different cleaning processes was to determine whether the wash water temperature played a significant role in the desorption of the retained previous cargo residues, always recognizing that SM is a polymerizable cargo, meaning the first stages of the cleaning should always be with cold water.

After cleaning, the test panels were then separately immersed into crude sunflower oil (CSFO) at 30oC and palm stearin (PS) at 70oC also for 28 days, at a contact ratio of 1 m2 of test panel to 1 m3 of vegetable oil. Again, the reason for the different cargo temperatures was to determine the effect of temperature on the desorption characteristics of the retained residues of SM and EDC.

After the completion of the immersion period, the vegetable oil was tested for the presence of SM and EDC using gas chromatography-mass spectrometry (GCMS).

The results are presented below and clearly show that for MarineLINE® 784, with its polymer modified high crosslink density, there is no detectable transmission of either SM or EDC into either of the samples of vegetable oil. The other cargo tank coatings do show varying amounts of transmission of SM and EDC into both types of vegetable oil.

Analysis of CSFO and PS for the Presence of SM and EDC

Conclusion

Under the conditions of this study, there appears to be almost no absorption and retention of SM and EDC from MarineLINE® 784, providing excellent protection against previous cargo contamination.

Advanced Polymer Coatings is continuing to investigate similar studies based on a variety of commonly carried cargoes to provide the customer with a better understanding of absorption, desorption and transmission characteristics, relating to more efficient and optimized cargo handling.

At APC, we understand the need for impermeable barriers. As a quality, premier coatings solutions provider we provide innovative, value-added coatings for the protection of your assets.

Acknowledgments

The author would like to acknowledge MarinSpec Associates Ltd. for their work in the evaluations contained in this report.