Cutting sulfur oxide emissions will make an impact on our environment and improve overall health.

The shipping industry has a few options to comply with the mandated, IMO 2020 - reduction of SOx emissions. It can switch to use a compliant fuel with lower sulfur content, an alternative fuel (e.g. LNG, methanol), or clean its exhaust gases with a "scrubber" technology to reduce the output of SOx.

APC understands the impending change the shipping industry is facing. As a provider of industrial coatings to protect your assets, we supply the right coating for your needs. We engineer a range of ChemLINE® coatings with its high chemical resistance to sulfuric acid to be used to line scrubber units.

In this article, we discuss IMO 2020, the impact exhaust gas cleaning systems (scrubbers) will have on our industry, and insights moving forward.

Content

- What are Scrubbers on Marine Vessels?

- How Do Exhaust Gas Cleaning Systems Work?

- Types of Marine Scrubbers for Use

- Pros and Cons of Implementing Scrubbers on Marine Vessels

- Scrubber Technology Market Outlook

What are Scrubbers on Marine Vessels? (And why does the shipping industry need them)

Scrubbers, or the technical term, exhaust gas cleaning systems (EGCS), or SOx scrubbers are used to remove harmful elements from exhaust gases. With strict rules starting in 2020, ships are implementing exhaust scrubber systems geared towards reducing sulfur.

How will the shipping industry comply?...

By retrofitting the ship's machinery with a scrubber system. By fitting an exhaust gas cleaning system that will reduce the sulfur content from 3.5% to 0.5%.

The enforced rules will help cut sulfur emissions that could prevent 150,000 premature deaths and millions of childhood asthma cases every year. Bloomberg NEF estimates some 4,800 vessels will be scrubber-equipped by 2025.

Watch the video on What is IMO 2020 for more insight on how the regulation will reduce the amount of sulfur oxides dispensing from ships and have benefits globally, especially on populations living close to ports.

Marine Insight, What Is IMO 2020, via YouTube

Extra Resource:

Ten Scrubber Questions Answered An in-depth questions and answers by The Maritime Executive, reviews acidification effect on seawater by scrubbers, types of emissions also reduced by scrubbers, and more.

How Do Exhaust Gas Cleaning Systems Work?

Scrubbers are used by ship operators globally. There are three types of exhaust gas scrubbers (EGS): open-loop, closed-loop, and hybrid.

Ship Insight cites in a scrubber,

"the sulfur oxides in the exhaust are passed through a water stream reacting with it to form sulfuric acid and are removed from the exhaust gas which then passes out of the system."

As an engine on a ship operates, it creates exhaust. Prior to the use of scrubbers on a ship, the exhaust would go directly into the atmosphere. With a scrubber, sulfur oxide is removed as the exhaust moves through a scrubber tower. The video below shows an example of water mixing with the gases to remove pollutants.

source: Maritime Training Services, Exhaust Gas Scrubbers & Caustic Soda Safety, via YouTube

EGCSA states the "scrubber wash water removes and converts sulfur oxides from the exhaust gases, so they are discharged in the wash water as harmless sulfate." The discharges are constantly monitored and subject to the IMO limits.

Most of the wet scrubbers operate with three basic components:

1. A vessel (scrubber vessel combines exhaust steam with water, either sea or freshwater)

2. A treatment plant (removes the pollutants from the wash water)

3. Sludge handling facilities (collects the excess sulfur to dispose of later)

Some scrubbers do not use water and we discuss the different categories in more detail in the next section.

Extra resources:

How do Scrubbers on Ships Really Work?

Exhaust Gas Cleaning Systems: Scrubber Overview

What is an Exhaust Gas Cleaning System? (Technical reference with images)

Types of Marine Scrubbers for Use

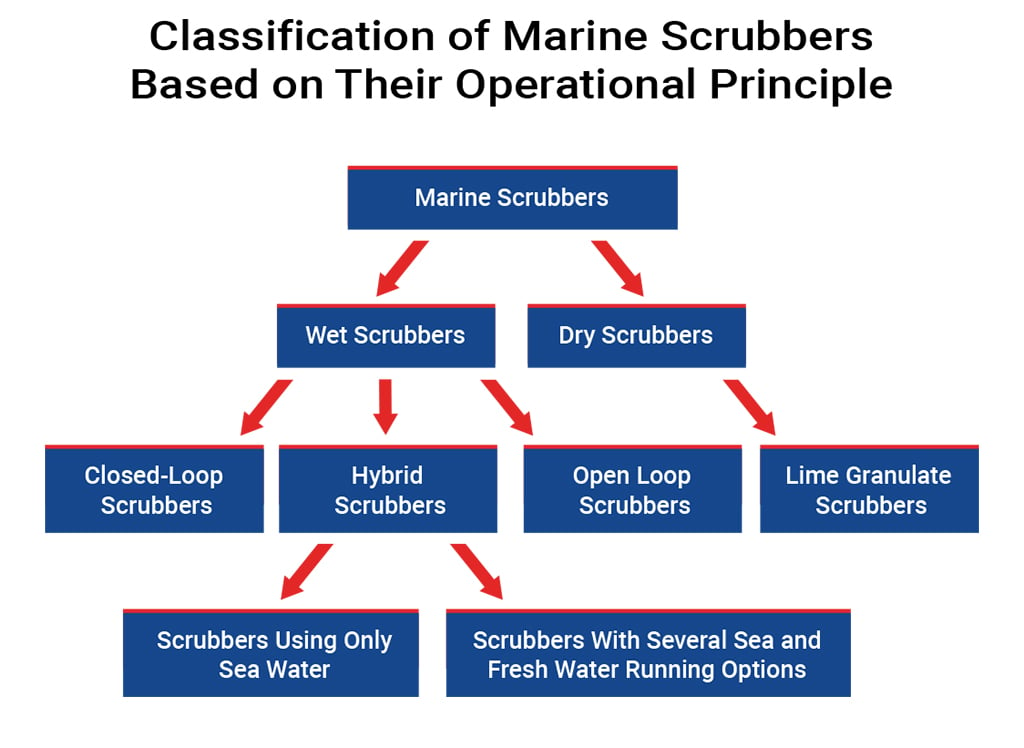

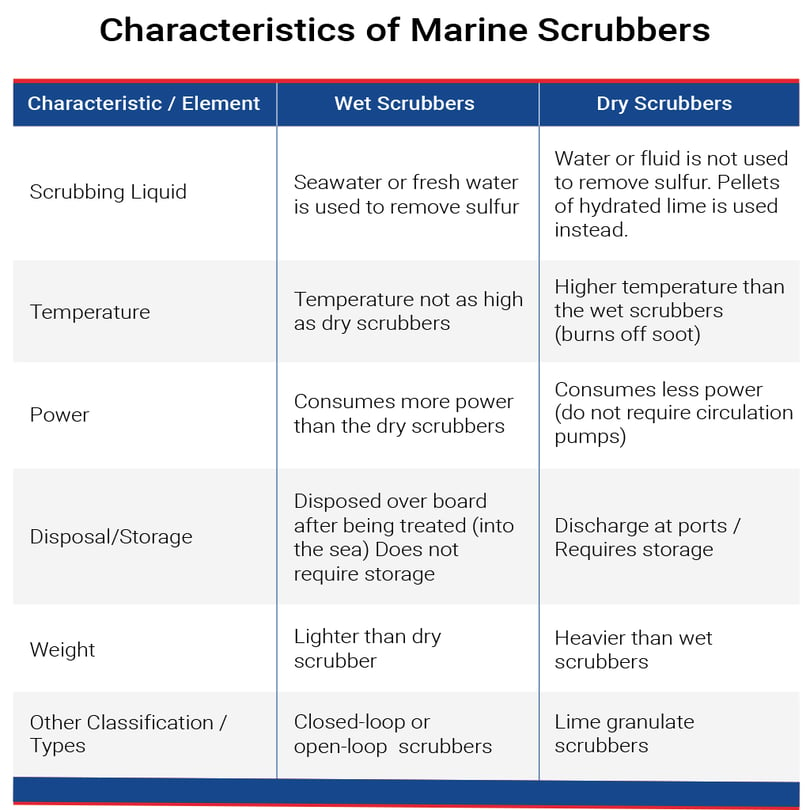

Scrubbers enable ships to use less expensive and a higher sulfur fuel while maintaining the emission standards set by IMO-2020. EGCS come in a variety of designs with two different classifications of scrubbers, wet scrubbers, and dry scrubbers. From there scrubbers can be categorized into:

- Open-loop EGS - takes in seawater for the cleaning process

- Closed-loop EGS - uses freshwater treated with alkaline chemicals

- Hybrid EGS - can operate with sea or freshwater

source: Marine Insight, A Guide to Scrubber System on Ship, October 2019

Wet scrubbers are more common and acknowledged as being the most efficient.

Below we compared the differences in a wet scrubber versus a dry scrubber. The choice of scrubber system to be installed on a ship can depend on the space available, area of operation, power of the engine, availability of freshwater, and more.

All types of scrubbers are allowed under IMO rules as long as they achieve the proper level of emissions.

Extra resources:

A Guide to Scrubber System on Ship

All You Need to Know About Scrubbers [Infographic]

Pros and Cons of Implementing Scrubbers on Marine Vessels

Technology comes with advantages and drawbacks. We know IMO 2020 - is opting for cleaner shipping for cleaner air. The video below covers significant benefits for both human health and the environment.

Benefits such as 77% reduction in SOx emissions from ships, a significant boost for health with reductions in pulmonary and cardiovascular diseases, prevent acid rain, and ocean acidification.

Cleaner Shipping for Cleaner Air

source: IMOHQ, IMO 2020 - Cleaner shipping for cleaner air, via YouTube

The IMO notes five beneficial key changes from IMO's Sulfur limit.

1. Cleaner air due to sulfur oxide reduction

2. Positive impacts on human health

3. Higher quality fuels to meet IMO 2020

4. Enhanced preparedness for ship operators, owners, and refineries

5. Ships will be monitored by authorities for compliance.

Shortcomings of Scrubber Technology

- Expensive to install (costly upfront investment than other options)

- Ship could be inactive while the installation occurs (Ship managers are currently quoting around six weeks in dry-dock for the retrofitting of a scrubber system)

- Scrubbers do not remove NOx, CO2

- Potential disposal issues

source: Exhaust Gas Cleaning Systems: Scrubber Overview

Scrubber Technology Market Outlook

Consistent compliance for sulfur reduction is critical. Within the next few years, "10 to 15 percent of ships are projected to install scrubber systems" to capture sulfur and fine particulate emissions before they escape exhaust funnels.

Based on technology,

"the wet marine scrubber systems segment is expected to dominate the marine scrubber systems market in terms of global market share and is expected to account for more than a 90% share of the total absolute dollar opportunity in the marine scrubber systems market by the end of 2028." (source)

Persistence Market Research (PMR) states the global market for marine scrubber systems will exhibit a steady 20.4% CAGR by 2028.

Moving forward, we need to continue to push for reduced emissions. Dr. Elizabeth Lindstad, Chief Scientist at SINTEF, shared a study that cites two-stroke engines with EGR (exhaust gas recirculation) and scrubbers are an effective way to meet the 2020 sulfur cap.

Conclusion

The shipping industry will become more environmentally friendly by regulation.

From APC's perspective, using the right coatings engineered to protect against corrosion will provide long term protection of your asset.

For tank owners, operators and lessors looking to gain the maximum versatility and a long service life for their assets, they need to look at a coating system that can handle the widest range of chemicals used in transport, has superior chemical resistance and product purity, cleans easily and is a proven performer in the transport market.

Image by Engin Akyurt from Pixabay