However, the shipping industry consumes 300 million tons of fuel every year, releasing around 3 percent of the world’s carbon-dioxide emissions into the atmosphere.

The shipping sector recognizes its power to change the impact on the environment and play a leading role.

At APC, we see customers’ desire to explore green transportation and more people wanting their companies to act responsibly for more significant decarbonization. As an industry leader in marine cargo tank coatings and filling the increased demand for high-performance tank linings, APC also witnesses first-hand the evolution the industry is experiencing and the critical role we play in the maritime value chain.

This article has incorporated several industry developments and discussions from various sources about the value of a green ship and potential strategies to increase energy efficiency and decarbonize global shipping. With MarineLINE® cargo coating protection, tanks can be cleaned faster and use less fuel for heating, reducing fuel consumption and emissions.

The shipping industry is dynamic, and the growing demand for tank containers and the urgency to take measures for reducing the carbon footprint is substantial. The increasing standards made by the IMO have triggered research and development of "green" technology for the shipping industry. The shipping industry has to create and apply innovative measures in order to comply with the new regulations.

Let’s get started . . .

Chapters

Chapter 1

What is Green Shipping/Green Marine?

The environment must be considered in all the details of shipping, from a build of a new vessel through its decommissioning. The International Maritime Organization (IMO) is helping to reduce the impact on the marine industry by regulating exhaust emissions, anti-fouling, ballast water, and more.

The industry will become more environmentally friendly by regulation. The International Maritime Organization proposed a 2020 Sulfur limit on the exhaust from the stacks of ocean-going ships. The IMO has called for ships to halve their total greenhouse-gas emissions by 2050.

Carbon emissions and other gases are caused by the burning of fuels in the environment. A green ship would leave the least amount of carbon emissions. "Green ship" is a name given to any seagoing vessel that contributes towards improving the present environmental condition in some way. Green ship technology adopts procedures to decrease emissions, consume less energy, and be more efficient.

Green Marine, a voluntary environmental certification program for the North American marine industry, addresses key environmental issues in regard to air, land, and water pollution. They offer a plan for maritime companies to reduce their overall environmental footprint.

Resources:

Bright Hub Engineering, Green Ship Design for Ship Building

Green Marine, Green Marine Environmental Program

Chapter 2

Cutting Sulfur Oxide Emissions to Improve Air Quality

The International Maritime Organization is taking action to clean up shipping emissions by reducing the sulfur content in ships' fuel oil. In response, the shipping industry started considering several solutions, including low Sulfur fuel oil (LSFO), marine gas oil (MGO), liquid natural gas (LNG) and even burning the current fuel and having scrubbers on the exhaust stacks.

The IMO required that all fuels used in ships contain no more than 0.50 percent sulfur.

"Public health experts estimate that once the 2020 sulfur cap takes effect, cleaner marine fuels will reduce ship-related premature mortality and morbidity by 34 and 54%, respectively, representing a ~ 2.6% global reduction in particulate matter 2.5 /PM2.5 cardiovascular and lung cancer deaths and a ~3.6% global reduction in childhood asthma."

[source: Cleaner fuels for ships provide public health benefits with climate tradeoffs]

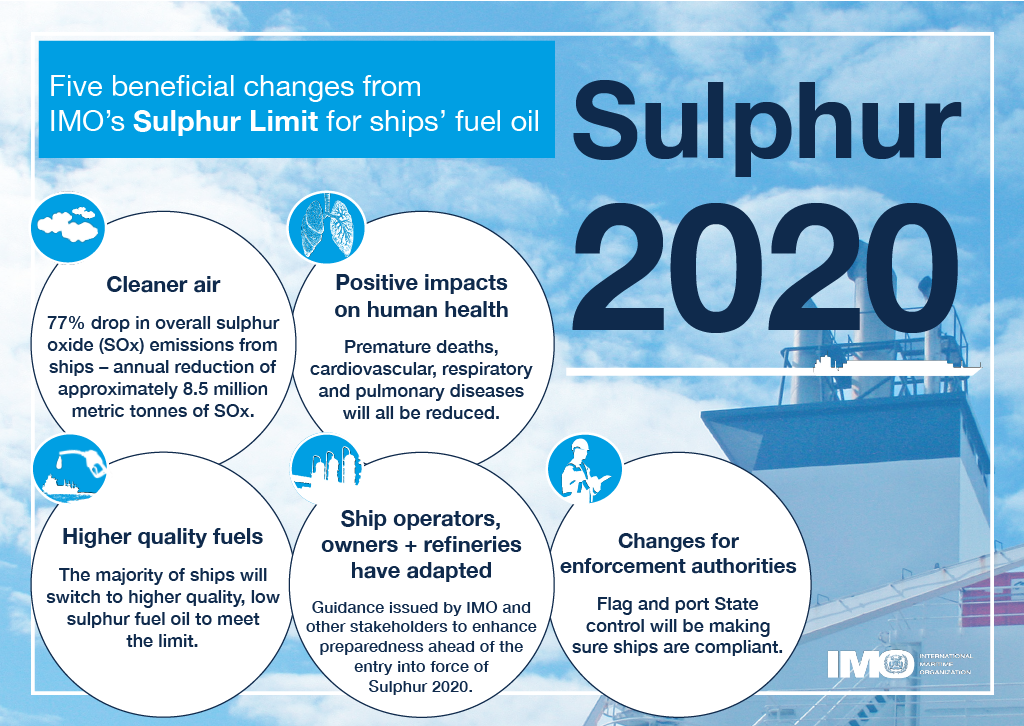

As the infographic by the International Maritime Organization illustrates below, there are 5 beneficial changes from IMO's Sulfur Limit for ships' fuel oil . . .

source: IMO International Maritime Organization, 5 Beneficial Changes - Sulfur 2020 - Infographic

According to IMO, five changes for sulfur limit are cleaner air, positive impacts on human health, higher-quality fuels, ship owners and operators adoption, changes to enforcement authorities.

Chapter 3

Ballast Water Needed to Reduce Hazards Associated With It

What is Ballast Water?

Ocean-going ships take on ballast water to maintain stability when traveling through water. Ballast tanks provide adequate stability to vessels at sea. It allows vessels to carry a light or heavy load while maintaining ideal buoyancy.

However,

Organisms and pathogens found in ballast water and sediments in ballast tanks have had an economic and ecological impact on marine biodiversity in many regions. The IMO is introducing regulations on several topics to reduce the impact of the marine industry on both the sea and atmosphere, ballast water being one.

The video below gives a quick overview of the ballast water cycle.

Marine Online, What is Ballast Water, via YouTube. November 24, 2016

What is a Ballast Water Management Plan?

According to Marine Insight . . .

The requirements of IMO Resolution A.868 (20) are:The global community, under the administration of IMO has adopted the “International Convention for the Control and Management of Ship’s Ballast Water and Sediments, 2004”. The convention is intended at stopping the introduction of superfluous aquatic organisms and pathogens through the discharge of ballast water and sediments.

- All officers and crew involved in ballast water management to receive proper training

- All ships to minimize the transfer of harmful aquatic organisms and pathogens

- All ships to develop and follow a ballast water management plan

- All ships to record all ballast operations

Seatrade Maritime News recently reported Optimarin—a Norwegian ballast water treatment system (BWTS) manufacturer, launched the first digital system to help ship operators in ballast water management.

Resources:

Marine Insight, Ballast Water Exchange and Management Plan

Seatrade Maritime News, Optimarin Goes Digital with Ballast Water Treatment

Chapter 4

19 Green Shipping Solutions to be Compliant

The shipping industry is responding with strategies to go "green." As IMO 2020 is in effect, shippers have some strategies prepared in order to become compliant.

Some are ready to implement immediately. Other strategies as presented by various industry sources are in the infancy phase.

Green Shipping Solutions to be Compliant . . .

1. Switching to Low-Sulfur Fuel

The move to lower sulfur content allows for applying advanced emissions control technologies that substantially lower the harmful emissions from diesel combustion. [source: Ultra-low-sulfur diesel: ULSD]

Marinelog reported that the recent transition to low-sulfur fuels is going "extremely smooth".

2. Slow Your Ship's Travel Time

Large ships might burn 280-300 metric tons of high-sulfur fuel oil (HSFO) a day at high speeds, but only 80-90 metric tons a day at slower speeds.

Slower travel may cut costs and help reduce emissions. [source: IMO 2020: The Big Shipping Shake-Up]

3. Incorporate a Ballast-Free System

Move towards a ballast-free system. Ballast water brings unwanted species. A ballast-free ship would reduce the potential hauling of contaminated water.

Limiting the amount of ballast taken is the first step in an effective ballast management plan.

4. Use LNG as Marine Fuel

LNG fuel helps in the reduction of air pollution. A small percentage of cargo ships are expected to run on liquefied natural gas (LNG), a fuel that has only recently advanced in the marine market.

LNG is now considered a mature alternative fuel option. However, there are many technology choices that need to be made depending on specific vessel design and operational requirements. [source: DNV, LNG as marine fuel)

5. Implement an Exhaust Scrubber System/Sulfur Scrubber System

Some ships limit their air pollutants by installing exhaust gas cleaning systems, also known as "scrubbers". This is accepted under the MARPOL Convention as an alternative means to meet the sulfur limit requirement.

The system is geared towards reducing sulfur or capturing sulfur before it escapes through the exhaust funnels. Bloomberg NEF estimates some 4,800 vessels will be scrubber-equipped by 2025. [source: How the Cargo Industry Is Cleaning Up Its Act]

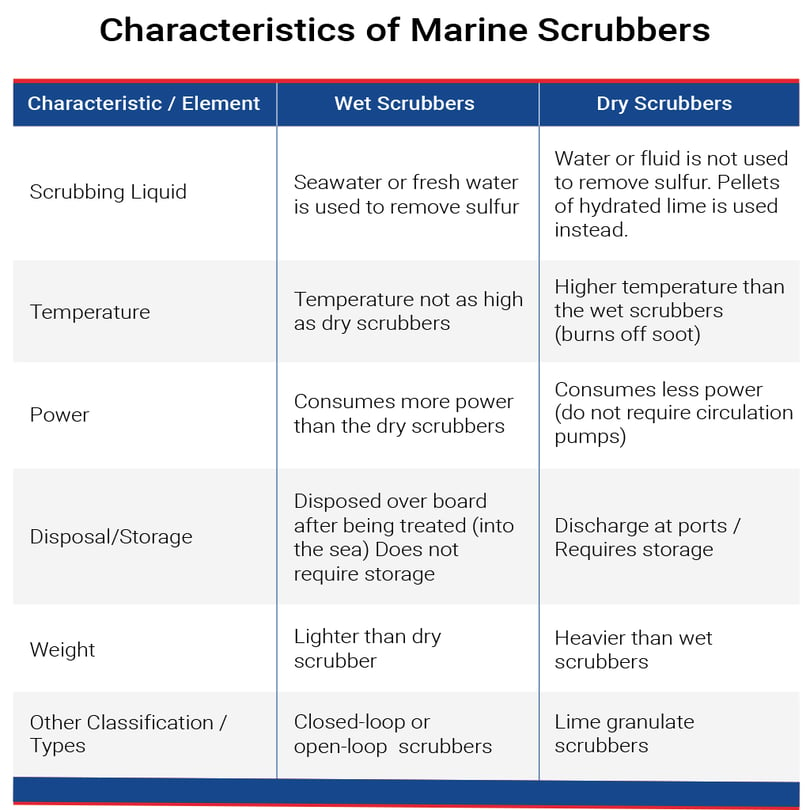

We compared differences in a wet scrubber versus a dry scrubber. The choice of scrubber system to be installed on a ship can depend on the space available, area of operation, power of the engine, availability of freshwater, and more.

All types of scrubbers are allowed under IMO rules as long as they achieve the proper level of emissions.

6. Use Speed Nozzles to Save Fuel

Speed nozzles improve the propulsion efficiency of the ship by saving power. By using speed nozzles, as opposed to traditional methods such as Kort nozzles to power your ship, you are saving fuel by approximately 5%.

7. Apply the Best Anti-Fouling Hull Paint

Anti-fouling paint (bottom paints) helps slow the growth of organisms that attach to the hull.

The condition of the hull (smooth hull) is essential in fuel efficiency. The speed of a ship decreases as its hull becomes infringed with marine growth. Applying correct paint at the right hull area can reduce the frictional resistance of the ship resulting in 3-8% of fuel savings.

8. Have a Proper Waste Heat Recovery System

Waste heat recovery systems are becoming more eco-friendly.

They will help reduce fuel consumption by converting the waste heat from the exhaust gases into steam. The steam can be used in other capacities, such as heating cargo area.

9. Use Wind Energy with the Sail and Kite Propulsion System

The sail and kite system will use wind energy to move a ship through the water.

According to Marine Insight,

"The specific towing kite is made in such a way that it can be raised to its proper elevation and then brought back with the help of a ‘telescopic mast’ that enables the towing kite to be raised properly and effectively."

This will help reduce fuel consumption and decrease NOx, SOx, and CO2 emissions.

10. Exhaust Gas Re-circulation System

In internal combustion engines, Exhaust Gas Recirculation (EGR) is a nitrogen oxide (NOx) emissions reduction technique used in gasoline and diesel engines. EGR works by recirculating a portion of an engine's exhaust gas back to the engine cylinders.

According to EGCSA,

"A proportion of the exhaust gas from the main engine exhaust receiver is recirculated to the scavenge air via a dedicated closed loop scrubber which removes damaging contaminants (PM, sulfur oxides, etc.)." [source]

11. Streaming Underbelly Bubbles

Streaming bubbles out of tiny holes in a ship’s underbelly can help to slice more cleanly through the water. According to Samsung, the technology can cut fuel consumption by 4 or 5 percent.

12. Submarine Robot Cleaners to Improve Fuel Efficiency

Grasses and other organisms grow on the hull of ships. Robot cleaners can strip away debris and improve fuel efficiency. Removing barnacles that attach themselves to the ships' hull can decrease a vessel's fuel consumption by as much as 20 to 40 percent.

13. Battery Boats

"In Norway, where the government wants two-thirds of all ferries carrying passengers and cars along its Atlantic coast to be electrified by 2030, Kongsberg Gruppen ASA is offering battery-powered ship engines and developing a short-haul electric container vessel." [source]

14. Rotor Sails to Harness the Wind

A.P. Moller-Maersk A/S is considering using a modern version of the old-fashioned sail to help power its ships.

The sails could potentially replace 20% of the ship’s fossil fuels, according to Norsepower Oy Ltd., which makes them. The spinning cylinders harness wind power to propel a ship.

Norsepower LTD, Norsepower Rotor Sail Solution via YouTube, February 17, 2017

The rotor sails can be used with new vessels or retrofitted to existing ships.

15. Reduce Fuel With More Efficient Steering Gears

According to Biofriendly Planet, there are two types of steering gears that are both eco-friendly and cost-effective: hydraulic and electro-hydraulic gears.

"The steering gears work by developing hydraulic pressure through the use of hydraulic pumps which are mainly driven by electric motors or sometimes through purely mechanical means. This pressure then triggers the necessary rotary movements in the rudder system allowing for a ship to turn safely.

By using one of these two efficient steering gears, you can help reduce your ship’s overall fuel consumption by approximately 4% on any given voyage."

16. Use of Green Hydrogen

Green hydrogen, an alternative fuel generated with clean energy, has been identified as the clean energy source that could help bring the world to net-zero emissions.

Green hydrogen is a fuel that is created using renewable energy. The resulting hydrogen is called green if the electricity is produced by renewable power, such as solar or wind. Because of this, it has the potential to provide the shipping industry power without emissions.

How is green hydrogen produced? . . .

Source: Hydro Tasmania, How is green hydrogen produced?

17. Reduce empty containers

The reduction of empty container movements will reduce fuel consumption, reduce congestion and emissions.

According to ResearchGate . . .

Empty container repositioning (ECR) is one of the most important issues in the liner shipping industry. Not only does it have an economic effect on the stakeholders in the container transport chain, but it also has an environmental and sustainability impact on society since the reduction of empty container movements will reduce fuel consumption, and reduce congestion and emissions. [source: Song, Dong-Ping & Dong, Jing-Xin. (2015). Empty Container Repositioning. 10.1007/978-3-319-11891-8_6.]

18. Sandwich plate system (SPS)

Structural maintenance programs are increasing and require an innovative approach. SPS is a process of composting two metals plates by bonding them with polyurethane elastomer core. The elastomer provides continuous support to the plates. This stops plate buckling and eliminates the need for stiffeners.

SPS Overlay is the "marine repair application of SPS technology that delivers a fast, non-disruptive and economical steel reinstatement and strengthening solution."

This process is beneficial to vessel crack repair to help save on cost, time, environment, and safety. SPS has a low carbon footprint.

Resources:

Ian Nash, Leo Maritime, and SPS Technology, Structural composites for vessel crack repair

SRS, Ship Repairers & Shipbuilders LTD

19. Use Cargo Tank Coating with Improved Cleaning Capability

Using the right cargo tank coating in a chemical tanker can positively impact a green ship from APC's perspective. APC's MarineLINE® cargo coating produces an ultra-smooth surface so tanks can be cleaned faster and use less fuel for heating, reducing fuel consumption and emissions.

Closing Thoughts

The IMO 2020 emissions standards are here. They are designed to protect the environment and curb pollution produced by the shipping industry. The demand for IMO-compliant products will continue to rise. Ships owners can reduce their sulfur emissions by implementing "green" strategies today and moving forward.

The ability to move swiftly between various cargoes is also important. Selecting the right coating extends the range of cargoes, reduces the time needed to switch them, and delivers the highest return on investment (ROI). As a quality, premier coatings solutions provider, we provide innovative, value-added coatings for the protection of your assets.