According to a new report by Grand View Research, Inc., the global antimicrobial coatings market size is anticipated to reach USD 21.5 billion by 2028, registering a CAGR of 13.1% over the forecast period.

Given the past year, you're probably the most familiar with sterilizers, the strongest type of public health antimicrobial product.

At APC, we strive to be a world-class specialty coatings provider. With that role comes the responsibility to be intimately familiar with applications to make a safer, cleaner environment and curb the spread of germs. Our commitment encourages us to stay on top of the latest advancements in the coatings industry.

This article looks at the antimicrobial solution from commercial products, i.e., building materials, foodservice equipment, and transport products to healthcare devices and supplies. We have included industry insights and developments from various sources about the workings of antimicrobial coatings.

[Bonus Content] Download our free PDF: What is Industrial Biofouling?

Controlling biofouling is accomplished in a variety of ways. We put together a guide to address biofouling management, its impact on industrial cooling towers, and the benefits of using an epoxy system to protect against chemical and atmospheric corrosion.

Get the PDF version to save to your desktop and read it when it's convenient for you. (No email required):

Let's first address...

What is Antimicrobial Coating?

The antimicrobial coating is an application of a chemical agent that stops the growth of the disease-causing microbe. While other coatings provide anti-corrosion resistance properties, the antimicrobial coatings protect against a broad spectrum of bacteria, mold, and mildew.

When microbes grow on a painted surface, they can stain and deteriorate the paint film. This reduces the coating’s integrity.

PRISM Media, a leading growth-oriented publication, says...

Coatings that contain an antimicrobial can inhibit the growth of these microorganisms, such as mildew and mold, protecting the film itself from degradation. In addition, antimicrobial agents inhibit the growth of bacterial odor. [source: In the Know: the Difference Between Antimicrobial, Antibacterial, and Microbicidal Coatings]

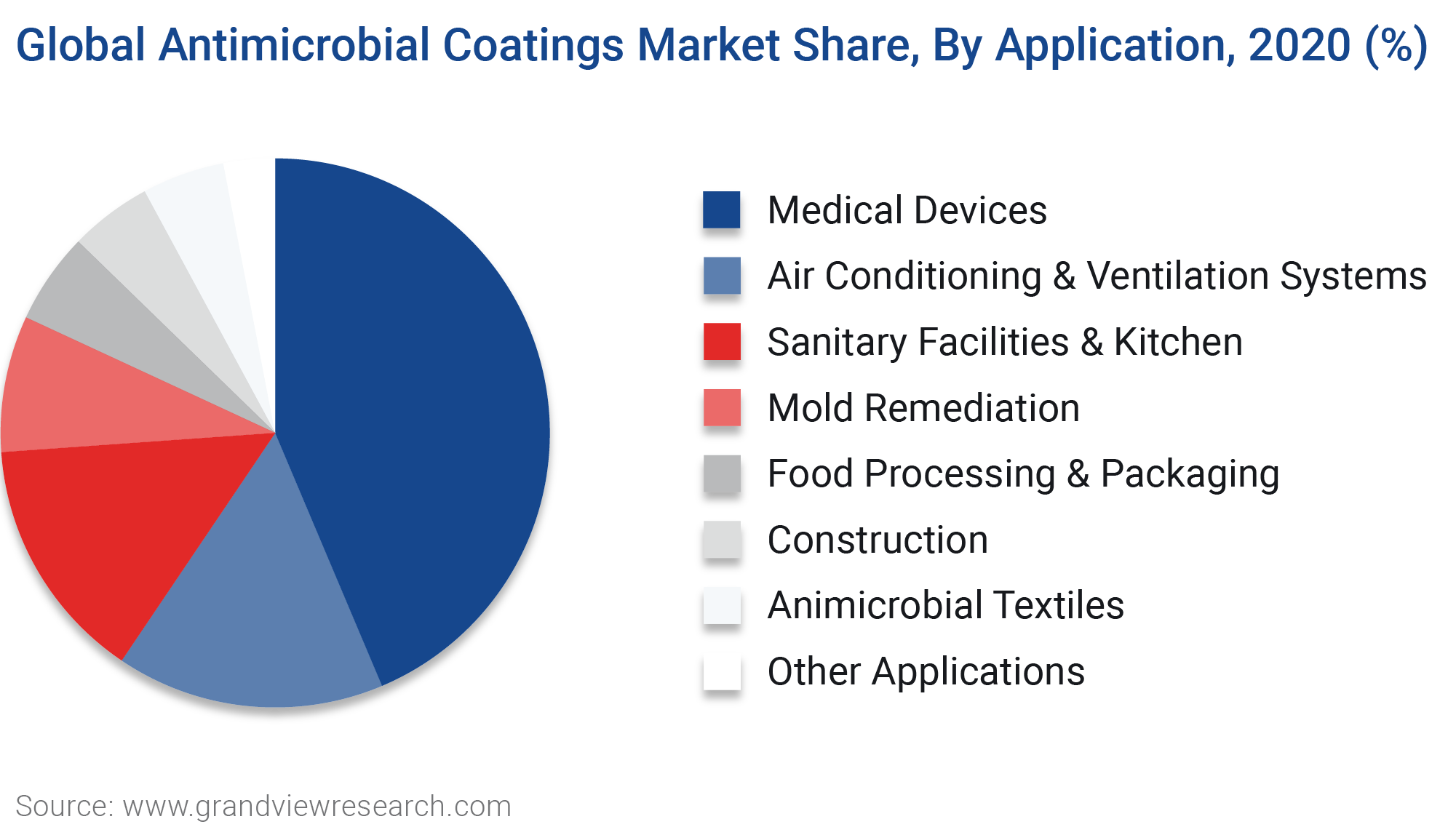

Global Antimicrobial Coatings by Application, 2020 (%) Insights

The applications are unlimited. From medical & healthcare, indoor air/HVAC, mold remediation, building & construction, food & beverage, textile, and others.

The major drivers influencing the growth of antimicrobial coatings are the increasing demand from the medical and healthcare sectors.

The medical devices application segment led the global market and accounted for more than 42% of the worldwide revenue in 2020. This high share is attributed to the product properties as they protect surfaces from microbes, including fungi, parasites, bacteria, and germs.

source: Grand View Research, Antimicrobial Coatings Market Size, Share & Trends Analysis Report By Product (Surface Modifications & Coatings, Antimicrobial Powder Coatings), By Application (Construction, Medical Devices), And Segment Forecasts, 2021 - 2028

How Antimicrobial Technology Works?

By definition, "antimicrobial" refers to something detrimental to a microbe.

Additives introduced into the coatings during the manufacturing process make them resistant to microbes. For example, additives such as silver ions inhibit germ growth.

The durable coatings continue to perform through harsh environments, water exposure, or excessive cleaning.

"The main way to combat the growth of bacterial cells on a surface is to prevent the initial adhesion of the cells to that surface. Some coatings which accomplish this include chlorhexidine incorporated hydroxyapatite coatings, chlorhexidine-containing polylactide coatings on an anodized surface, and polymer and calcium phosphate coatings with chlorhexidine." [source]

The video below shows how BioCote® Antimicrobial Technology protects a surface from harmful microbes, including bacteria and mold.

source: BioCote® Ltd, BioCote Antimicrobial Technology in Action via YouTube

On an untreated surface, the bacteria thrive and reproduce considerably. However, on a treated surface, the bacteria cannot survive and reduce by up to 99.99%.

What are the different types of antimicrobial coatings?

Markets and Markets says...

Industrially, several types of antimicrobial coatings are available in the market. Among these types, silver-based antimicrobial coatings are prevalently used owing to their high efficacy rate compared to other types such as copper, titanium dioxide, and zinc-based, among others.

Understanding Antimicrobial Versus Antibacterial

As mentioned, coatings that contain an antimicrobial inhibits the growth of microorganisms (mildew and mold). When these coatings are used, it protects the film itself from degradation.

Antibacterial is a type of antimicrobial used to inhibit the growth of bacteria.

Microban International, a global leader in antimicrobial additives and odor control solutions, says,

Antimicrobial technologies minimize the presence of bacteria, mold, and fungi. In contrast to antibacterial agents, antimicrobial substances offer a greater level of product protection by continuously inhibiting the growth of microbes on surfaces for very long periods.

The broad-spectrum performance of antimicrobial substances makes them perfect for use in hygiene-critical environments such as schools, hospitals, and commercial kitchens. Typical active ingredients include silver or zinc.

Antimicrobial technology typically contains one of three active inorganic ingredients:

- Silver ion antimicrobials: suitable for a wide range of materials and applications, including medical coatings, plastics, and food-contact products.

- Zinc antimicrobials: a broad-spectrum antimicrobial that is commonly favored for its antifungal properties.

- Copper antimicrobials: often used as a preservative and popular for medical products and surfaces.

Since we are talking about effective solutions against microbes that live in water, soil, and the air.

Let's mention one more: Biofouling.

Biofouling is the build-up of unwanted material on surfaces. Biofouling is different from antimicrobial. Antimicrobial coatings are based on preventing disease-causing organisms on the surface, and biofouling prevents organisms that attach to the coated surface in general.

Biofouling composition includes organisms ranging from bacteria, algae, and barnacles in a marine environment where noticeable aquatic growth appears on ships and underwater structures. Biofouling increases ship hull drag, corrosion, fuel consumption, and engine stress.

In these instances, marine coating systems are applied to ships to protect the hull from deterioration and keep up the vessel's appearance. Biofouling is an undesirable process in which biological molecules and organisms adhere to a surface. This process causes severe adverse effects in various fields, including marine transportation, healthcare, and water distillation.

On the other hand,

Industrial biofouling occurs in power plants, water treatment systems, and food/beverage industries. Problems include pipe blockage, decreased membrane flux, and contaminated water.

Conclusion

Most surface coatings are based on synthetic polymers, industrially produced, and form tough, durable films when applied to surfaces. At APC, our chemical coatings are high-performance specialty coatings that can resist corrosive acids, alkalis, and solvents at various temperatures.

We want the selection of a lining for your project to be easy. We want you to have confidence that you not only made the right choice but that everything was done correctly to give you the peace of mind that the lining will exceed its expected lifetime.

We have decades of experience helping customers choose the suitable coating, guiding them through the process, and providing personnel on-site to ensure that everything goes right.

Get a quote today to see if our ChemLINE® polymer coating can fit your asset’s needs.

Or you can talk to a coatings expert today to learn more about how our proprietary technology in our line of industrial coatings can help you optimize your asset use, reduce downtime, and prevent corrosion.